Replacement Side Roll Tarp for End Dump Trailers

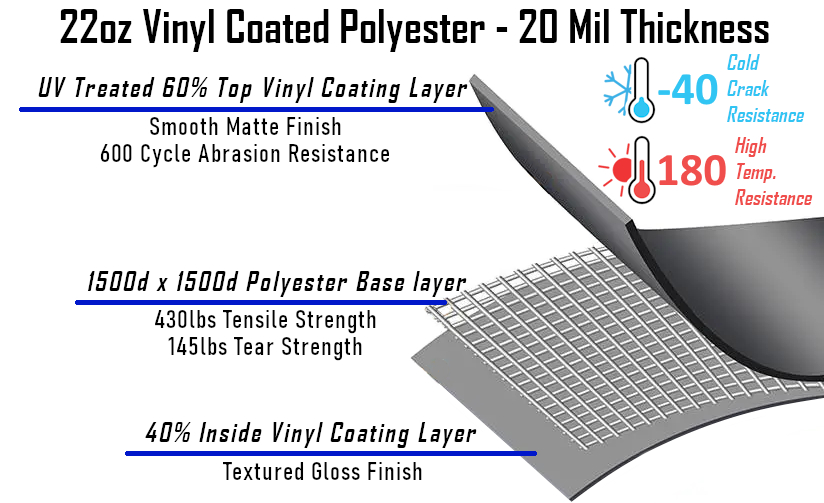

- Constructed out of high grade 22oz vinyl coated polyester

- Heat sealed waterproof seams

- Two-Ply webbing reinforced hem front and rear

- Webbing reinforcements every 5’ on drive pocket

- 4” Pocket Driver Side / 2” Pocket Passenger Side

- Includes 18" tapered tail flap

Description

What is an end dump trailer?

End dump is a style of semi-trailer designed for cost effective long distance transport of heavy duty materials. End dump trailers feature a rear dump gate plus a front mounted hydraulic lift cylinder to tilt the box quickly unloading its contents. End dump trailers are available in steel or aluminum which is often two layers thick. Half round end dump trailers provide the best material flow but straight side end dump trailers provided the highest load capacity. Depending on the application it could have a full frame, quarter frame, or be frameless. Most end dump trailers are 26’ to 42’ long but some are as short as 20’ plus a few manufacturers offer a 45’ trailer.

What industries use end dump trailers?

Agriculture: Lime, fertilizer, compost, and plant byproducts.

Construction: Excavating and grading during site preparation.

Demolition: Concrete debris removal and scrap metal recycling.

Landscaping: Mulch, rocks, sand, soil, and stone.

Mining: Minerals, ore, and coal.

Recycling & Salvage: Metal shavings, e-waste, and food residuals.

Road building: Asphalt, gravel, and millings.

Waste Management: Non-toxic solids or hazardous waste collection.

What type of tarps do end dump trailers use?

There are three styles of tarp systems used on end dump trailers.

1) The most common is a side roll tarp. Side roll tarp system uses a pair of tubes to roll the tarp from side to side. Many feature a locking latch plate on the driver side but some are secured with ratchet straps. These could be operated by a manual hand crank or an electric motor.

2) Flip systems are the second most common tarp system for end dump trailers. Just like on a dump truck bed these use a pivoting arm mounted in the center to flip the tarp from the front up and over the load to the back.

3) On accordion style cable tarp systems the tarp is mounted to a series of bows that are secured to a cable. A pair of pulleys is used to roll the cable which pulls the tarp towards the front or pushes it towards the rear.

18oz Fabric vs 22oz Fabric

18oz vinyl coated polyester is the industry standard fabric for side roll tarps but for end dump trailers we sell substantially more 22oz. About 90% 22oz vs 10% 18oz. End dump trailers tend to more haul abrasive loads that other styles of trailers. Plus the loading process often damages the trailer creating bumps and burs in the trailer’s finish that will be constantly rubbing against the tarp.

Bottom line is 22oz vinyl fabric boosts tear strength and abrasion resistance by 50% but costs 40% more. If you own a trailer with dents in the bows, dings in the top rail’s finish, and scratches across the tailgate this extra strength will likely increase life expectancy enough to justify the added expense. If you own a damage free trailer that haul less abrasive loads like grain upgrading will not add life expectancy so save some money and go with 18oz fabric.

CLICK HERE for 18oz Fabric.

What tarp Width do I need?

10’ or 120” is the most common tarp width for end dump trailers. Trailers with a latch plate installed on the driver’s side may require a 123” tarp. 114” wide is common for side roll tarps that are secured on the driver’s side with ratchet straps. Trailers with oversized bows will require extra width. If the existing tarp has performed well you can unroll it to the fully extended position and measure across.

With the pipes inserted the tarp will measure about three inches skinnier than it actually is.

CLICK HERE for Custom Width End Dump Trailer Tarps

What tarp Length do I need?

Collecting the length is much trickier on end dump trailers than other styles. For the vast majority of trailers measure from the top of the tailgate towards the front creating at least 6” of overlap onto the front cap. On some trailers the tarp and its pipes stop well short of the tailgate. If the existing tarp has performed well, we always recommend measuring it to learn the length.

If the existing tarp has worn prematurely across the front and or the rear chances are that is a length issue. Now while ordering this new tarp is the time to correct that.

CLICK HERE for Custom Length End Dump Trailer Tarps

What size tail flap do I need?

About 85% of the end dump trailer tarps we build feature a tail flap. Our standard flap hangs down 18” and match the trailer’s width.

This flap starts 4” in from the outside edge of the passenger side pocket.

Tarps that stop short of the tailgate will require a flap longer than 18”.

Trailers with hinges that protrude above the tailgate will require a flap that is narrow enough to fit between the hinges. Plus the offset will need to be increased to clear the passenger side hinge.

Will it fit my side roll tarp system?

This replacement hopper bottom tarp will fit 90% of tarp systems on the road today. It fits manual hand crank as well as electric roll tarps. If your tarp system has the four features described below this tarp will fit.

This replacement side roll tarp will fit end dump trailer brands like Armor Lite, Clement, East, Mac, MTM, Trailstar, and Travis.

Where is it made?

Every single tarp we sell is Made in the USA. Cullman, Alabama to be exact. Zero imported tarps sold. Period!

Our team is sweating but this is not a sweat shop. That’s hard work mixed with Alabama humidity on Real Americans who sacrifice the best 40 hours of their week to support their family and this great country.

Your decision to Buy American provides us the privilege of rewarding these workday warriors with competitive wages, health insurance, and paid time off.

Our standards for materials, workmanship, quality control, and employ wellbeing will never allow us to be the low price leader but the overall value is responsible for a century of repeat business.

Lookout Mountain Tarp opened in 1923, was incorporated in 1927, and is a fifth generation family owned local business.

When will it ship?

Unless it's one of our stock tarps that we keep in stock, we'll usually have the tarp built and ready to ship within 5 business days. Fulfillment within one week is always our goal. Please note we are closed Saturday and Sunday, as well as most typical holidays.

How do you ship?

Most of our tarps are rolled up and placed inside a standard box using UPS Ground. UPS Ground takes 1-5 business days depending on how close you are to Cullman, Alabama.

UPS offers Saturday delivery in some markets but for the most part Saturday and Sunday are not counted in that calculation. For orders of 10+ tarps please contact us before ordering so we can get a quote for LTL delivery which will likely be more cost effective.

Product Videos

Details

- End-Dump-Trailer-Tarps

- End-Dump-Trailer-Tarps

- Lookout Mountain Tarp

- Made to Order - Ships in 5 business days

- New

Categories

Shipping Information

- Item Requires Shipping